#11 floating home remodel – i-beam craned in

We’re two and half months into remodeling our floating home for a second and final time. More on the whole remodel later, but here’s a look at likely the most interesting part of the whole project – craning a 34′ i-beam overtop of our neighbor’s homes and dropping it into the second story of our home. And to spice it up the forecast was calling for 50 mph winds in the afternoon (fortunately we did this in the morning and beat the weather!)

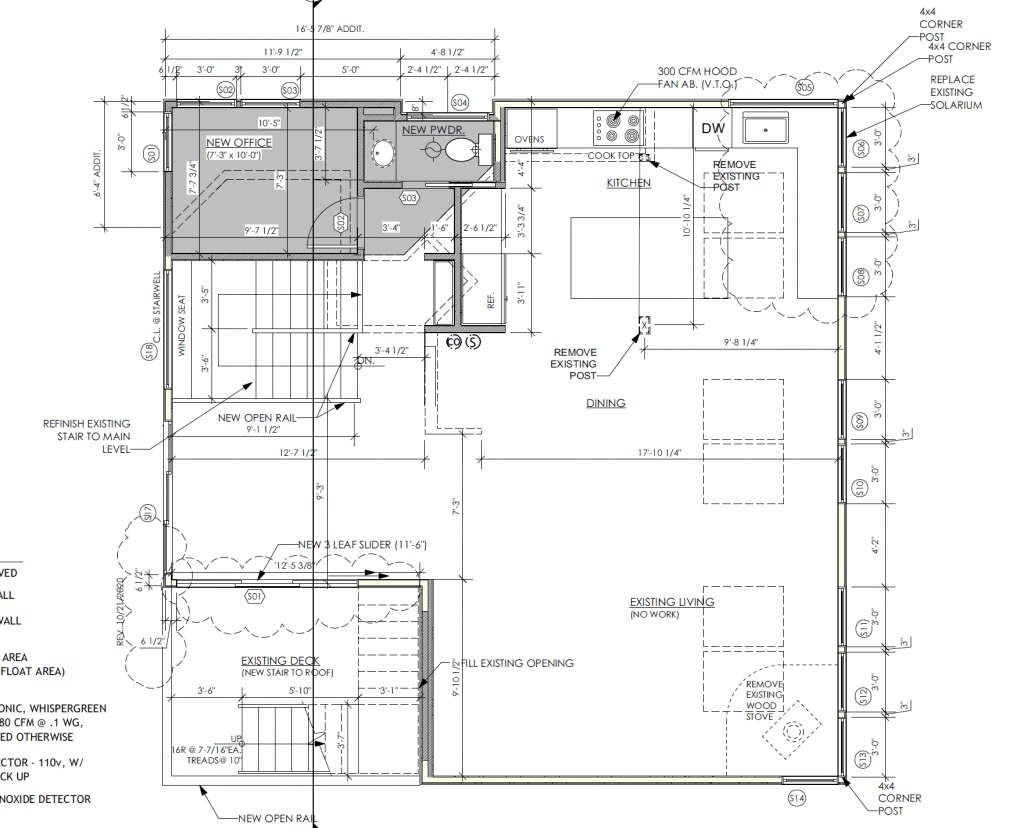

Like all remodels, we’ve had some scope creep. Okay, a lot of scope creep. What started as replacing a (very) leaky roof, new siding and expanding a bedroom snowballed into also re-working our entryway, moving a powder room and a whole new kitchen. As part of remodeling the kitchen, “since we had the roof off anyway”, we decided to eliminate a pesky column in our kitchen. It made a great spot for charging your phone, but was an eye sore and would stand out even more in the new kitchen design.

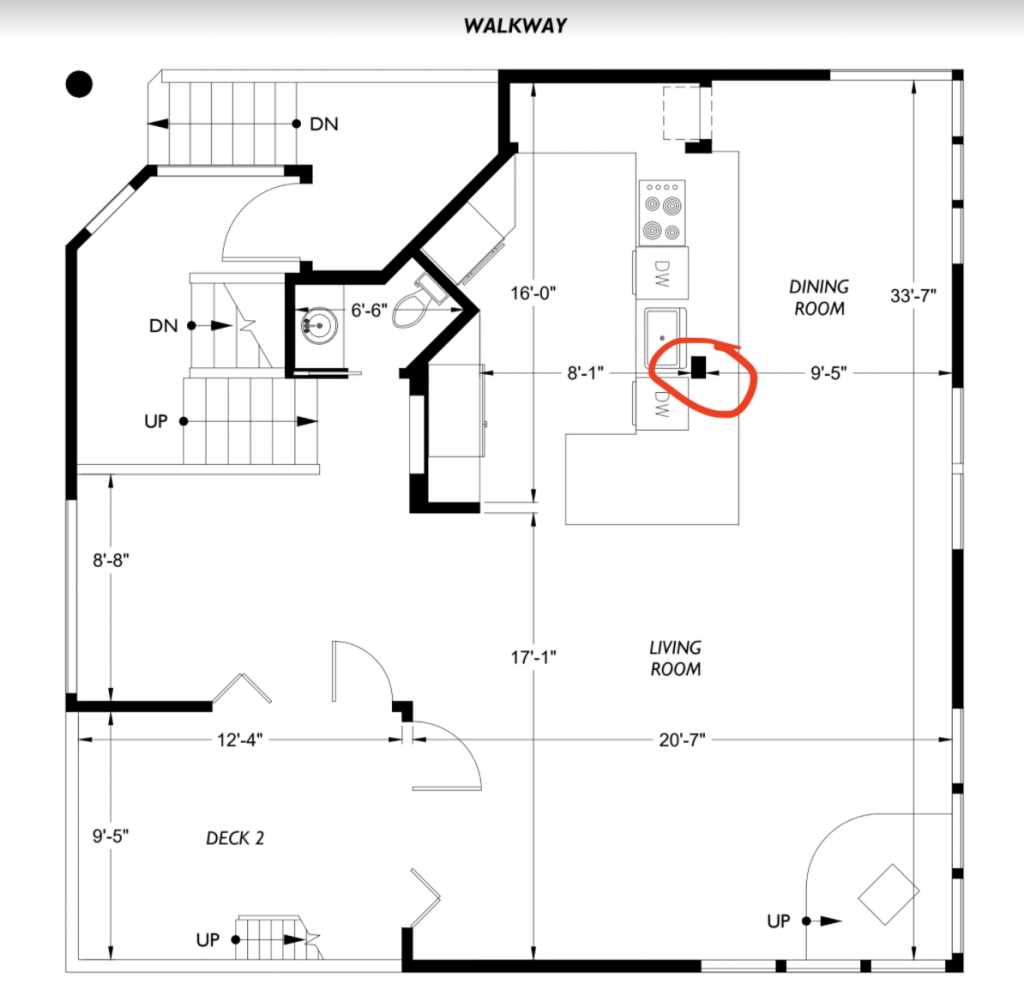

Here’s the old kitchen:

In the updated floor plan below you can see we’re changing a lot more than the kitchen! But looking just at the column, it is right where the chairs for the island would be which would have been awkward.

While we could have shifted the column south a few feet to sit between the kitchen and dining area, we decided since the leaky roof was coming off anyway, this was a great chance to remove the column by replacing the existing glulam beam with a 1,700 pound 34′ long i-beam.

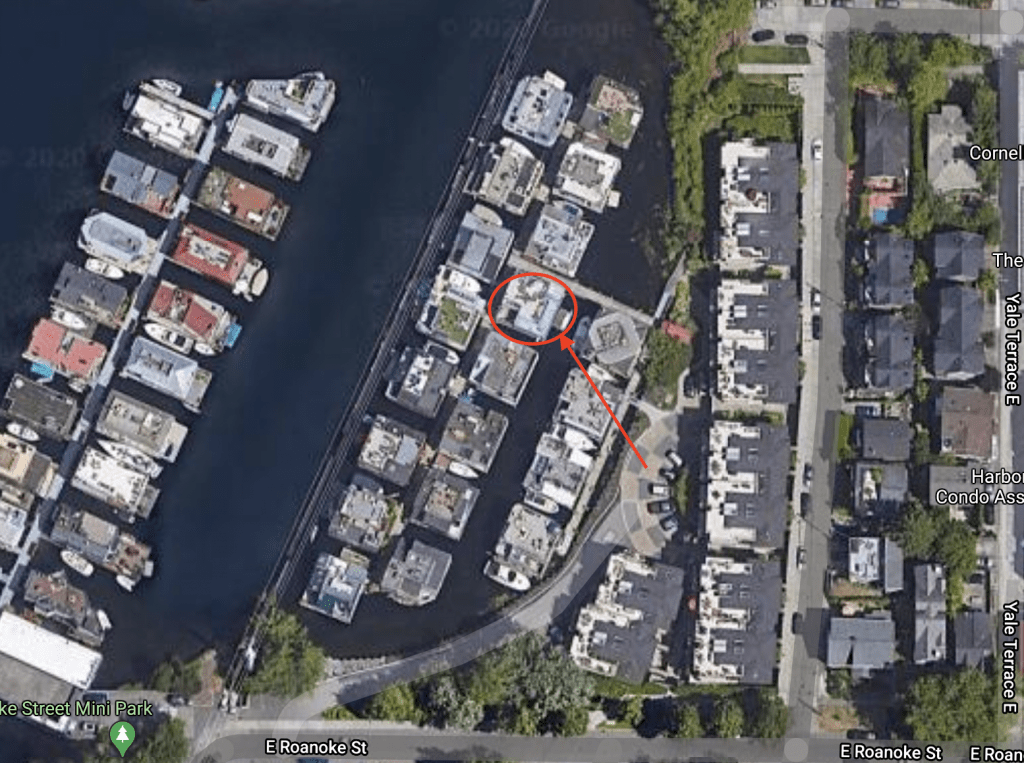

Of course, living on the water, such a project is a lot more complicated than if we were remodeling on land. Our contractor, Dyna, explored all the options (including a crane on a barge) and concluded that craning the beam 120′ from the parking lot was the cheapest and easiest option.

To do so required a 90 ton crane from Magnum Cranes, the Liebherr LTM 1090-4.1. The thing was a beast!

The i-beam, as well as it’s two-story support columns and a second, smaller i-beam arrived on a 50′ trailer which the driver skillfully backed down our curving driveway with the water on one edge.

The crew started by craning in the two-story tall steel supports the big beam would sit on, then they got to work on the i-beam itself.

The east roof (left side) was completely removed (and will be replaced).

Thankfully we beat the big weather but we got dumped on that night with a torrential downpour. I didn’t get a video, but I stopped by the house at night and water was pouring straight through the middle of our house. However, we’re not too stressed, we’ll be doing a lot of drywall work anyway!

We owe a big thanks to our neighbors for letting us block the garage and take over the parking lot for a morning. And for being cool about a big stick of metal flying over their homes.

Cost:

- TBD: engineering to figure out size of i-beam and supports

- $1,200: 50′ i-beam with next day shipping from Spokane to Dyna’s metal shop.

- TBD: prepping the i-beam

- TBD: trailer i-beam from shop to our house

- $5,000: Crane rental for their 4-hour minimum with a 3-person crew. (They were done in two hours.)

- TBD: metal supports, ripping open two walls to install them, re-drywalling them, etc.